By Omar Riahi

From An Interview with Jeroen Bello and Selamawit Belli at The Battery Show 2025

The rapid growth of electric vehicles has created a critical need for battery materials that are both high-performing and sustainable. With global EV sales projected to surpass 26 million units in 2025, the industry faces unprecedented pressure to develop batteries that meet performance, cost, and environmental goals. Battery manufacturers struggle with challenges including thermal management, material scalability, carbon footprint reduction, and recyclability, while ensuring next-generation designs remain safe and efficient. In this article, you will learn how Dow leverages deep material science expertise, integrated supply chains, and customer-focused innovation to address these challenges, enabling readers to understand, evaluate, and implement sustainable solutions in EV battery technology.

Application Expertise: Translating Needs into Solutions

Bello opens the conversation by highlighting Dow’s unique approach: “Our application expertise is really what sets us apart. We bring our material science into each application, always asking: Why silicone? Why our chemistry? By understanding the role of chemistry in specific applications, it is possible to address customer challenges with qualified and proven solutions or develop new materials from scratch.” Belli adds, “Our technical service experts, or TS&D[JB1] [SB2] , engage in in-depth discussions with customers. They listen, ask about the challenges, and help translate those needs into the right formulation. Often, when a customer faces a big challenge, they come to us because of our in-depth knowledge.”

This customer-centric approach means Dow is not just a supplier, but a strategic partner in innovation. “If a customer requires a novel, next-generation battery, we work with them to create or adjust a formulation tailored to their needs,” Bello explains.

From Raw Materials to Sustainability

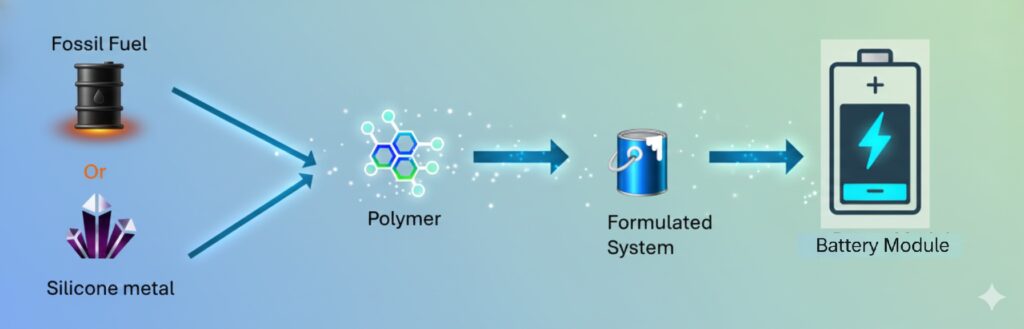

Dow’s value chain integration is another key enabler. “We are back integrated in a lot of our solutions,” Bello notes. “The process begins, from silicon metal, to silicone polymers to develop formulated silicone solutions and fossil fuels to polyurethane[SB3] solutions. That means we can develop the formulated advanced materials to address the needs, for example, of a thermal conductive adhesive in a battery management system.” Belli elaborates, “Working with Dow offers more than just a formulated product. We customize the formulation for specific needs. For example, we develop the building blocks from our molecules, resins and even catalysts to enable products to create new reactions.” [JB4] This integration also drives sustainability. “Being completely backward integrated enables us to offer a significantly lower carbon footprint compared to others in the industry,” Bello says. “In Brazil, for example, we produce sustainable silicon metal with a lower carbon footprint through clean energy and responsible sourcing, as well as open and closed-loop solutions by feeding waste products back into our process.”

Battery Recycling and Design for Recyclability

With battery recycling a hot topic, Belli shares Dow’s perspective: “We’re assessing how recycled materials play into areas where we’re strong. In the battery space, we’re exploring opportunities, but right now, our biggest impact is helping customers design batteries for recyclability.”

Bello emphasizes, “Our bonding technology can help the industry take batteries apart and access valuable minerals. We’re helping customers design batteries that are easier to recycle.”

Global Reach and Local Innovation

Dow’s global presence is a strategic advantage. “We are present in China, Japan, Korea, Europe, and North America,” Belli says. “China is leading in battery adoption and mobility intelligence. Everything we develop there, we can leverage across regions.”

Bello adds, “The car is becoming a supercomputer, and you need more thermal interface materials to keep electronics cool. We work across automotive, semiconductor, and consumer electronics industries, leveraging knowledge globally.”

Cross-Industry Innovation

Dow’s breadth of expertise allows it to transfer innovations across industries. “Nothing is unreachable or unthinkable,” Belli asserts. “Our participation in many markets enables us to leverage learnings and apply them into the automotive industry, ranging from mattresses to car seats. We have acoustic solutions that now help make EVs quieter. Our self-sealing tire technology means you don’t need a spare tire, freeing up space and reducing weight.”

Bello points out, “Electrification require three times as much silicone content as internal combustion vehicles. That’s a significant opportunity for innovative and new solutions.”

The Value Chain Approach

The interview closes with a powerful message: “Come to us with a gap or unmet need, and we’ll help figure out how to build it and get there,” Belli says. “It’s really a value chain approach. Vehicle design is changing, and new knowledge is forming. Dow plays in a multitude of industries, and we leverage that expertise to drive mobility forward.”

Bello sums it up: “We’re not just solving today’s problems—we’re preparing for tomorrow’s challenges. That’s our strength.”

Dow’s holistic approach, combining deep technical knowledge, sustainability, and global-local innovation, positions it as a key player in the rapidly evolving battery and mobility landscape. As Bello and Belli make clear, the future of mobility is not just about materials, but about partnerships, adaptability, and vision.

Quotes from the Interview

“Our application expertise is really what sets us apart.” Jeroen Bello

“We can change the ingredients to make it do what it needs to do.” Selamawit Belli

“We’re helping customers design batteries that are easier to recycle.” Jeroen Bello

“Nothing is unreachable or unthinkable.” Selamawit Belli

“Come to us with a gap or unmet need, and we’ll help figure out how to build it and get there.” Selamawit Belli

Summary

Dow’s approach to battery materials and mobility solutions is defined by deep technical expertise, a fully integrated value chain, and a commitment to sustainability and innovation. By partnering closely with customers, leveraging global insights, and adapting solutions across industries, Dow is not only addressing today’s challenges but also preparing for the future of electrification. As Jeroen Bello and Selamawit Belli emphasize, the company’s strength lies in its ability to turn complex needs into practical solutions, making Dow a driving force in the evolving landscape of electric mobility.

Key Takeaways

- Customer-Centric Innovation: Dow’s technical service experts work closely with clients to translate challenges into tailored solutions, often developing new materials for next-generation batteries.

- Integrated Value Chain: The company’s backward integration, from raw materials to finished products, enables unique flexibility and sustainability advantages.

- Sustainability Leadership: Dow’s processes, such as closing the loop with waste products and local production, significantly reduce its carbon footprint compared to competitors.

- Design for Recyclability: Dow helps customers design batteries and components that are easier to recycle, supporting a circular economy in the EV sector.

- Global Reach, Local Impact: Innovations developed in leading markets like China are leveraged globally, ensuring Dow’s solutions remain relevant and effective worldwide.

- Cross-Industry Expertise: Dow applies knowledge from diverse sectors such as home acoustics and mattress technology, driving creative solutions for EVs.

Future-Focused:

The company is committed to solving today’s problems while preparing for tomorrow’s challenges, positioning itself as a key partner in the future of mobility.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

About Tim Meyer

Tim Meyer is EV Technology expert specializing in renewable energy solutions and sector coupling. With over 27 years of experience in technology and management within the renewable energy and energy industries, Tim has held executive positions, including Chief Technology Officer at DirectNu Energy and board member at Inductive Robotics.